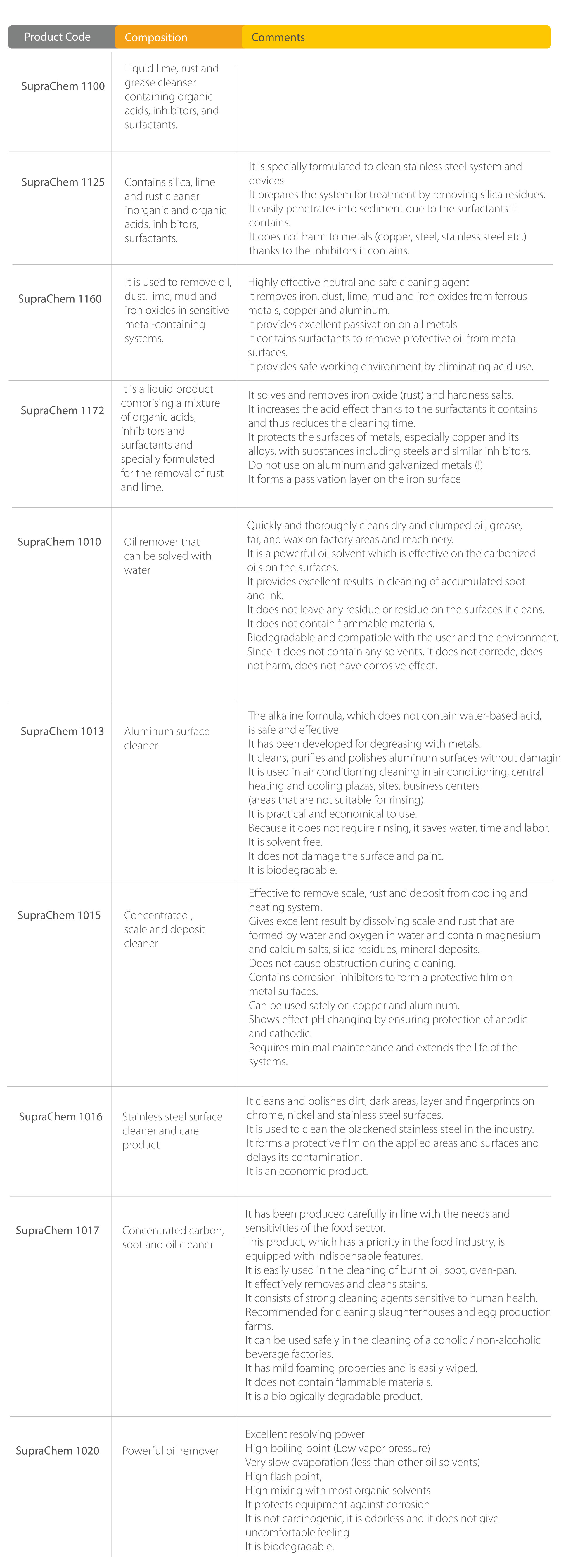

Industrial maintenance and commercial cleaning chemicals have been scientifically formulated to deliver significant performance benefits, improving the speed and efficiency of many cleaning and maintenance activities. Non-distilled industrial water contains mineral salts that bind to metal, especially hot surfaces. These scale deposits, usually calcium and magnesium compounds, are a plague to the operating efficiency of air compressors, heat exchangers, vacuum pumps, boilers, cooling towers and other water-wetted equipment. This results in billions of dollars in lost revenues due to equipment down time, increased power consumption and Lime scale build-up clogs pipes in heat exchangers, boilers, and other industrial equipment.maintenance costs associated with scale removal.

SAVE MONEY

Descaler offers an instant return on your investment. After all, lime scale is a costly nuisance that reduces production efficiency. Here are production problems caused by scale build-up;

- Volume – as pipes become restricted, pumping horsepower (and amperage) must be increased in order to maintain production volume.

- Heat-Transfer – as exchange surfaces become fouled, thermal efficiencies decrease, compromising production.

- Mechanical Failure – the weight of scale causes bearing failure in rotating equipment such as pumps and mixers.

MULTIPLE USES

- Heat exchangers, air compressors, power plant boilers, piping systems and evaporating equipment

- Water-wetted equipment in refineries, utilities, paper mills, chemical plants, foundries and rubber plants, to name a few.

- Food processing plants, meat packing plants and breweries. (NSF registered)

- Sewage disposal plants, water treatment facilities and other municipal water handling operations.

- Any piece of equipment that is water-cooled